Next-level production planning software

A digital twin is a powerful thing for manufacturers. It can answer questions like:

- How can I get products to market faster?

- Which specific areas can be optimized to improve operations and reduce costs?

- Where can I reduce errors and defects on the production line?

Ultimately, the answers to these questions can reveal new business models and processes that drive more revenue.

The secret to making the most out of production planning and control starts with choosing the right digital twin. That’s why we wrote this next segment of the Ultimate Guide to Simulation Digital Twins. It will help you think the right way about digital twins, choose metrics that matter, and help your team be even more effective in their jobs.

Digital twins have become increasingly popular for companies looking to get more out of their data. It’s easy to see why too. Digital twins help production planning and control teams get a better understanding of their production processes and create more resilient supply chains while reducing costs and inefficiencies.

Digital twins do this by giving you a near-real-time visualization of a discrete object or holistic view across an organization to help you optimize for performance. For example, a Simulation Digital Twin in manufacturing gives you a 360-view across an organization to help you optimize for performance through all your value chain.

Today, a production planning manager on your team might start with data trapped in excel spreadsheets, emails, sensors, and internal databases to gather relevant information. Next, he tries to gain an understanding of the links between plants, machines, production steps, and so on. He may try to gather all of this data into basic production planning software to begin understanding the intricate interdependencies in this network. But things are changing quickly, and with that, the data changes. (Something production planning teams know all too well during pandemics like the COVID-19 crisis.) Your production planning manager knows that he’s working off of incomplete and perhaps outdated data, but without much flexibility in the current tool, there’s not much he can do.

Eventually, he does pull together a plan to get factories and production moving again. But both time and money are being left on the table with the outdated and sub-optimal production planning software.

Without a digital twin, fast-moving, complex production scenarios are nearly impossible to track. You’d have all the data, but it would be stored in multiple places. Most importantly, the model wouldn’t account for all of the interdependencies between different components. Your digital twin brings all of those interactions together to help you get a 360-degree view of your full production process.

With that knowledge, you can create simulations that optimize your production process with all of the relevant data and priorities in mind.

If you’re ready to take that jump and use a digital twin to make your manufacturing data more powerful for your team, you need to start by comparing different digital twins to find the best one for your business unit.

Step 1: Bring stakeholders into the digital twin selection process

Before you even decide which digital twins you’re going to evaluate, you need to bring internal stakeholders into the process. The digital twin you choose is going to be working with data from different departments within your company, so it’s important that everyone is bought in.

The question you need to ask yourself at this point is: Who else collects and uses data that your digital twin will handle?

There’s a good chance your supply chain team stores data that your digital twin will need access to. A stakeholder from the supply chain team should be part of the buying process.

What about your factory management team? There’s a good chance that your factory management team uses tools that handle key production data. A stakeholder from the factory management team will likely be part of this process too.

If you have a team or an internal evangelist championing the move to digitization and really embracing the implementation of Industry 4.0 tools – by all means, that person should be a part of the process. (Since you’re reading this guide, there’s a very good chance that the change agent is you!)

You don’t need each stakeholder individually evaluating each digital twin and production planning software, but you will need their input on various parts of the selection process. At the very least, talk to each stakeholder and let them know why you’re looking into digital twins and what you hope to get out of it.

Step 2: Define the challenges you want your digital twin to address

There’s another big question you need to answer before deciding which digital twin is best for your company: What is the reason you’re looking to use a digital twin?

It’s easy to get caught up in the fact that you need a digital twin because it will help you build complex models, but what are you actually hoping to get out of that? Building complex models isn’t going to necessarily make you more data-driven. Nor is the goal specific enough to address all of the questions you’re looking to answer. It’s just a step along the way.

To choose the right digital twin, you need to define your use cases ahead of time.

Take some time to think about which areas and processes you want your digital twin to help with. Talk to your other stakeholders about their ideal use cases. From there, try to identify three or fewer ideal use cases. Limiting your use cases to just the top three will make it easier to evaluate all of the digital twin types and, finally, vendors. By making this an inclusive effort, you’re setting yourself and this new initiative up for success to be more broadly adopted across your team and organization.

Here are four main types of digital twins:

- Parts twinning – Discrete Twin

- Product twinning – Discrete Twin

- System twinning – Composite Twin

- Process twinning – Digital Twin of Organizations

We’ll go into more detail about each type of digital twin and the use cases each one is best suited for in the next step.

Once you’ve defined your use cases, spend some time studying your potential digital twins. Look at industry research; identify the product landscape; hear what industry analysts are saying; talk to colleagues at other companies who use digital twins. Does your ideal use case fit with what any of these digital twins can deliver on? If yes, start making a list of production planning software that offers this type of digital twin.

Step 3: Determine the digital twin needed

In order to select the right type of digital twin, you need to get a handle on the range of goals that your production planning team needs to accomplish. Looking at the full spectrum of what your team is accountable for will give you the digital twin type that can grow with you – regardless of how big or small, complex or straightforward the problem.

To get an idea of which digital twin you’ll need, start by focusing on your use cases. Which tools do you need to accomplish the specific use cases that you laid out in Step 2? Make a list of those tools. What simulations or visualizations are currently being created to help address those use cases? What do you wish you could do that you currently cannot given your current set of tools?

Next, make a list of all the tools and touchpoints that interact with your different use cases in one way or another. You’ll want to include existing production planning software, databases, excel spreadsheets, product management tools, and factory management tools, just to name a few.

At this point, go to your other stakeholders and double-check that you haven’t missed any important tools that will need to be connected.

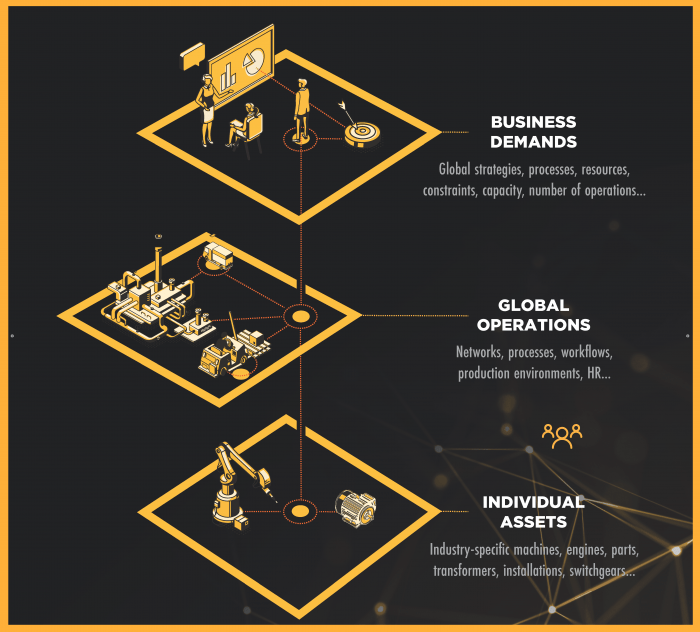

Now the types of digital twins themselves actually work within a hierarchy, starting from the simplest type that gives limited information and capabilities. Each level builds to offer more sophisticated digital twin possibilities, meaning more and more complex production planning problems can be solved as you work with more powerful digital twins.

Now let’s see where your use cases and digital twin types line up: